OEM Die Casting Mold Bulk Suppliers – Hot Runner Plastic Injection Mold – DT-TOTALSOLUTIONS

OEM Die Casting Mold Bulk Suppliers – Hot Runner Plastic Injection Mold – DT-TOTALSOLUTIONS Detail:

DT-TotalSolutions has very rich experience in designing and building molds in hot runner system.

The advantage by using hot runner:

– For some complex part and part of too thick or too thin, hot runner system is a must to make sure plastic flow run in full.

– For precision small parts in multi-cavity, hot runner system is also a must both to ensure full shot and save plastic material therefore to save the molding production cost.

– By using hot runner system, molding cycle time can be reduced by around 30% or more. This means your daily molding output can be greatly increased.

– By using complete hot runner system, plastic material wastage is 0. This is a very considerable cost especially for some special material which are very expensive.

– For some special plastic material with poor flow character, to avoid short-run issue, hot-runner system is also a necessary design.

– For plastic material with high-temperature required or with high Glass-fiber, special attention must be paid when designing and building hot runner system. Special steel and machining are required. DT-TotalSolution has very good relationship with all the big hot runner system makers like: HUSKY, Moldmaster, Synventive, YUDO, EWICON… We have been working together and keeping making new improvements for more than decade. With rich experience and knowledge to both mold and hot runner system, we can guarantee tool quality from the very beginning till mass production.

However, not every tool is suitable to be designed and built in hot runner system. There are some soft plastic material with super fast flow, it will be better to use cold runner instead. Also for some very low-volume project during prototype period, it’s more economic and suitable to use cold runner instead.

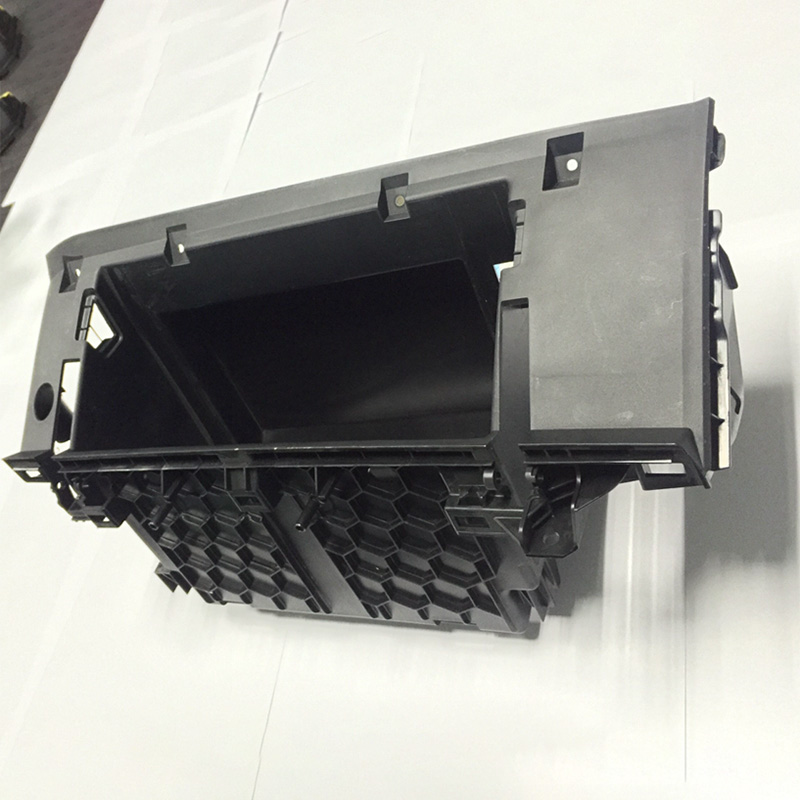

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for OEM Die Casting Mold Bulk Suppliers – Hot Runner Plastic Injection Mold – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Surabaya , Japan , Russia , Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!