China wholesale Die Casting Mould Part Products – Insert mold injection molding manufacturer – DT-TOTALSOLUTIONS

China wholesale Die Casting Mould Part Products – Insert mold injection molding manufacturer – DT-TOTALSOLUTIONS Detail:

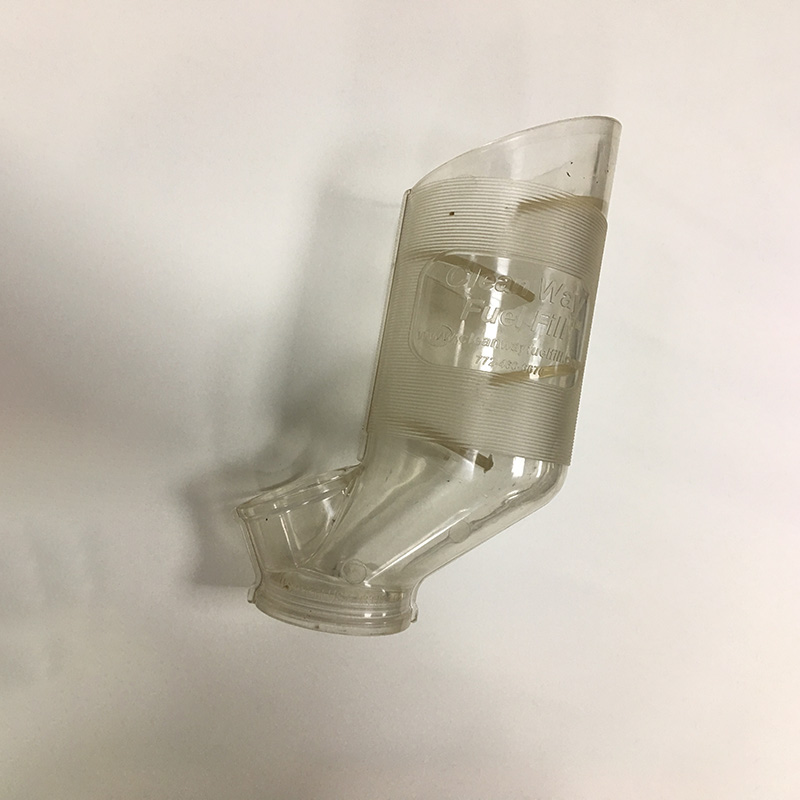

This picture shows molds for very precision insert mold to over molding metal inserts. The key point is to the metal-inserts positioning.

Another typical insert-molding project we did was TERMINAL connector for telecommunication. See below picture for reference:

For small precision insert molding, it’s much easier to use vertical molding machine with rotating-working-table by using 2 cores to improve positioning precise and molding efficiency. In this case when one core is closed for molding, the other core is to be inputting metal-inserts which can be done either by manpower or by robot, the total cycle time can be as short as less 10seconds depends on different projects. This is very widely used for telecommunication precision parts and electronics products.

However, in case of some bigger parts for most of home appliance or for automative parts, vertical molding with rotating-worktable is not suitable. As most of these parts are big and the tools are too big as well.

Either insert molds / molding for small parts or for big parts, DT-TotalSolutions has accumulated very rich experience to design and build the tools.

For many other plastic product defects, mold quality takes considerably high proportion, please refer to the following description:

Molding cycle: The more reasonable and optimized the mold structure is (the reasonable selection of mold materials, the reasonable selection of processing technology, etc.), the corresponding mold molding cycle can be improved.

In the mold design, the gate location and waterway layout will affect the molding cycle of injection molding. The short molding cycle will directly improve the efficiency of injection molding production and increase the production capacity of the injection molding machine, and it also means a reduction in production costs.

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for China wholesale Die Casting Mould Part Products – Insert mold injection molding manufacturer – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Hongkong , Australia , Swiss , We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.