OEM Custom Stamping Suppliers – Disposable drink cup – thin wall parts – DT-TOTALSOLUTIONS

OEM Custom Stamping Suppliers – Disposable drink cup – thin wall parts – DT-TOTALSOLUTIONS Detail:

For this cup, it was a mold with 12-cavity at only 12seconds cycle time. It is a successful project of multi-cavity thin-wall tool from DT team.

The key point of this tool:

– plastic wall thickness is very thin with only 0.8mm

–due to big EAU, it has to be big mass production and requires to be at least 12-cavity tool

–Required molding cycle time is 15sec.

–To keep each cavity injected in balance and same weight, it is also an essential point we need to pay additional attention to.

To meet above requirements, we have to use best hot runner system and machine all the steel / inserts very precisely. It must to be a one-time perfect job, mold cannot be failed from 1st time.

Detailed and careful mold-flow analysis was dong on this tool to make sure best injection size and gating way for full shot successfully.

Mold-master in valve pin hot nozzles were used for this tool. All the injection system including the related plates and injection inserts are machined by high-speed CNC machining with CCD full checking. By doing so, we can ensure best injection in balance and flow.

Considering the thin-wall, we have used high-speed injection molding machine for better filling and molding. Proper injection molding machine for proper project is very important to complete project successfully.

After mold test, FAI report, the related mold testing videos and pictures are all provided together to customers. This has become our standard routine for each mold.

By strictly controlled from the very beginning and throughout all the procedure, we are able to achieve shipping this tool within 7weeks from PO releasing. It was quite a success project we proudly have done.

Before mold shipping, we always take at least 4hours simulation-run to make sure our molds can continuously operating without any issue. The related injection parameters are always provided together to customer.

If you are interesting in consumable or disposable food packing products, please do not hesitate to speak to us. Our technician team are always more than happy to discuss new technology together!

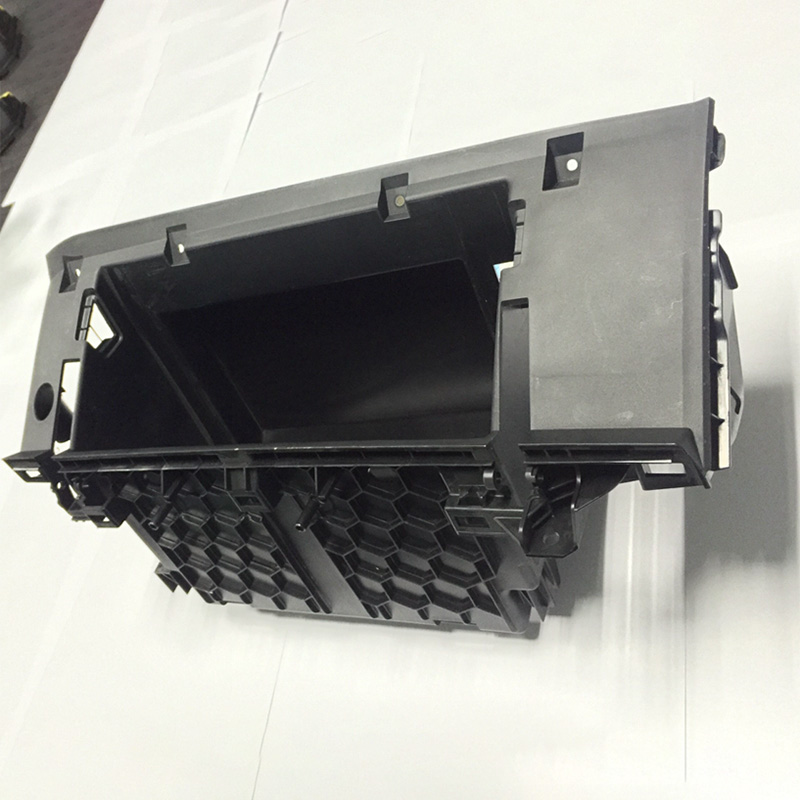

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for OEM Custom Stamping Suppliers – Disposable drink cup – thin wall parts – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Sao Paulo , Johor , Singapore , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.