OEM Die Casting Custom Auto Parts Manufacturer – Gas-assisted mold – DT-TOTALSOLUTIONS Detail:

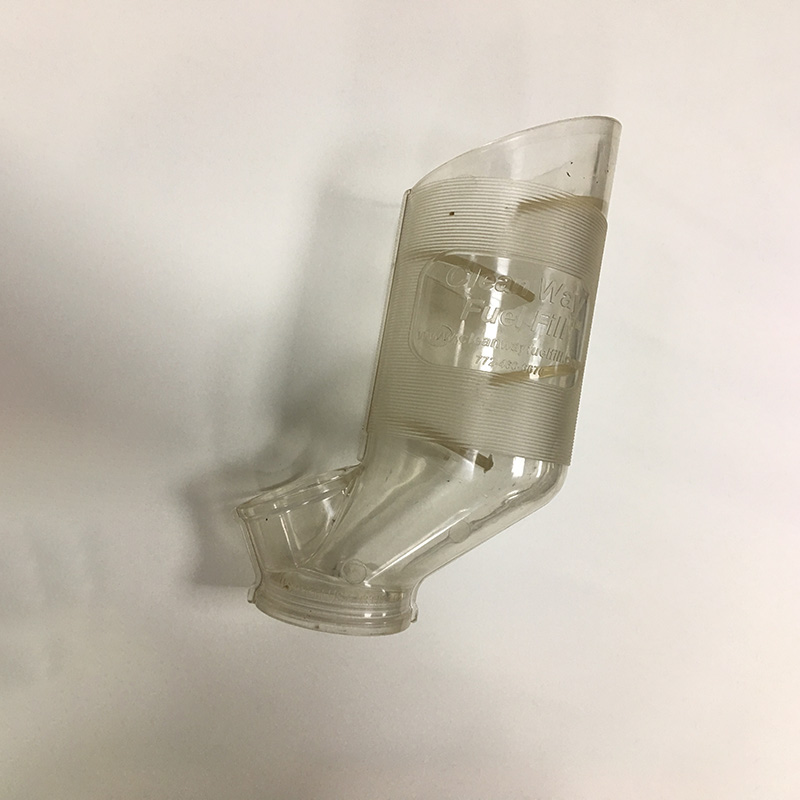

For this kind of handle molds, gas-assisting is needed to make sure part in full-fill and good appearance. This is a very mature technology widely used in thick-wall plastic parts.

Due to function requirement, the parts need to be very strong and stiff like steel. So the part designers have to increase the part wall-thickness. However for most of plastic arts with thickness over 5mm, it gets very tricky to get parts in good appearance. To make the part manufactureable, we proposed to use gas-assisting technology.

The key point is to analyze the best gas-injecting position during DFM stage. We would do mold flow analysis and internally discuss the best solution based on mold flow report and our previous experience on similar projects. During tool design stage, we need to pay extra attention to the room for gas injecting and other mold features like sliders and lifters. All the components must be working harmoniously without any colliding, and the mold must be running for thousands of or millions of parts continuously without any problem.

Come to DT-TotalSolutions, we will give you the best solution in both function and sustainability for thick-wall plastic parts!

For many other plastic product defects, mold quality takes considerably high proportion, please refer to the following description:

Raw material-production cost saving (runner material) : The design of the mold runner system will affect the weight of wastage generated during injection molding. These scraps are actually an increase in production costs.

The level of production automation: When designing the mold, it is necessary to consider the realization of injection molding production automation. Such as smooth ejection, no need for post-processing, stable production and no quality risk. If the mold cannot meet the requirements, there must be an additional operator during production, which will inevitably increase labor costs and increase the instability of product quality.

Post-processing work: The mold design is reasonable, and the product meets the requirements, there is no need for post-processing, such as flash repair, gate cutting, orthopedics, full inspection, etc…

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for OEM Die Casting Custom Auto Parts Manufacturer – Gas-assisted mold – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Latvia , Ecuador , Yemen , As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.