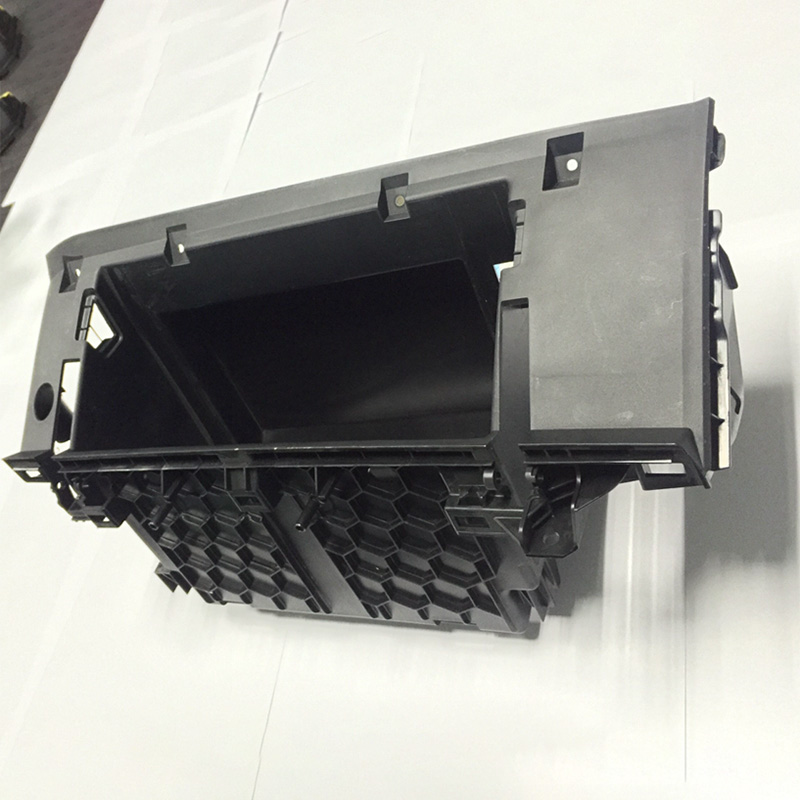

OEM Extrusion Manufacturers – Special tunnel mold in PPS – DT-TOTALSOLUTIONS Detail:

This is a part made from PPS which needs very high temperature during molding and high temperature on mold;

But to ensure part dimension, it is important to have the cooling enough so that to minimize part deformation.

The third challenge for this part is the how to demold the part which the feature is very special to be ejected in normal solution.

From the video you can clearly see how the demolding mechanism on this mold is functioning. We mechanically push the curved tube shape core up before ejecting the part out. This is quite an old school solution for such a unique part, and we think it’s a genius idea for such shape of feature. We consulted some mold experts and we finally figured out this solution which we highly appreciated for all the help from our team workers, partners and friends in the field.

Back to topic about PPS plastic material itself. This is a engineering material which need a melting temperature between 300-330℃ when doing injection molding. This requires high temperature for melting screw bar on molding machine and also makes the cavity and core in mold at very high temperature. So to make sure part with minimum deformation, it is very critical to have sufficient cooling in the mold. We have designed sufficient cooling channels that everywhere can apply to like cavity, core, inserts and plates. This was a typical mold we built years ago while 3D printing inserts technology was not so developed as now, otherwise we would try to use this technology on it at least it is worthy to try.

To test this tool we used special screw bars that can sustain high-temperature, and having our molding expert to set correct molding parameters for this tool. Thanks to all the detailed well controlling all through out the whole tooling process, our first trial went on quite successful. We can’t thank enough for our customer’s help and support for this project. This is how our partnership relationship between customers formed, that is projects to projects through years of cooperation!

We look forward to take more challenges together with you! If you have interesting projects need someone with heavy technique background to help you fulfill, please feel free to contact us at any time! DT-TotalSolutions team will be always at your side!

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our enhancement strategy for OEM Extrusion Manufacturers – Special tunnel mold in PPS – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Irish , Juventus , Austria , We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!