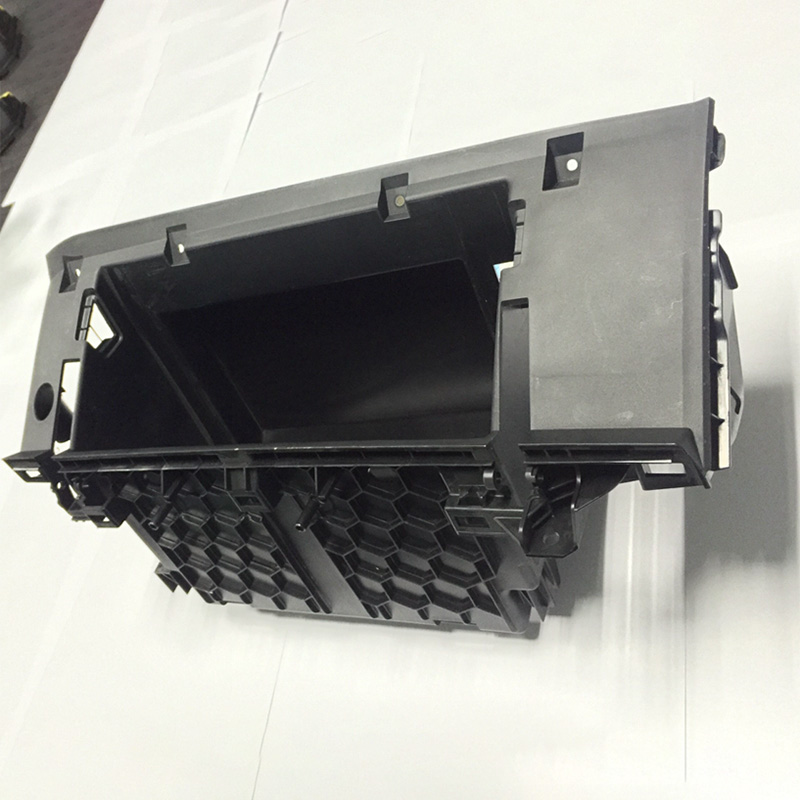

OEM Plastic Arts Factories – Auto lamp cover – DT-TOTALSOLUTIONS Detail:

This is a tool made from 2 components in 2 different plastics. The 1st shot is made from ABS+PC and the second made from PC.

The big challenges for this tool is:

— Part is high cosmetic visual part so the surface is critical

— The adhesiveness between the 2 stiff plastic parts is critical for function and the very key point for the success of this tool.

Considering the high requirement on the part surface and ensure part adhesiveness, we planed perfect processing scheme to build this tool from the beginning.

Firstly, a full detailed mold-flow analysis was conducted on this part at the very beginning, including analysis on plastic flow, plastic melting lines, air trapping, part deformation, plastic characters of flow and adhesiveness.

Secondly, all of our technical team having meetings to discuss this project based on the mold-flow analysis report and our experience on similar product. Our molding technicians of plastics export also joined the meeting and proposed the very important professional suggestions to improve adhesiveness by injection, cooling optimization.

Thirdly, based on our meeting results, we provide our rough solutions to this tool by providing detailed DFME report to customer for tooling designing and building concept communication. Throughout the process, our technical people are directly discussing with customers promptly. Instant technical communication is always available.

Fourthly after DFME confirmed by both party, we start to do detailed 3D tool design. For this tool it takes us around 4 working days to provide the complete 3D tool design drawing.

Fifthly, for the cosmetic part surface and adhesiveness surface, we use high-speed CNC machining center to ensure both surface quality and dimensional quality.

Sixth, every week we make sure customers are kept updated about all the processing status.

Last but not the least, for this tool testing, it is essential to use correct molding machine and good parameters. We are proud that our molding technicians helped us fulfilled this task successfully.

This mold was shipped to Europe, but we have been keeping following up for feedbacks yearly and make sure all the tools we delivered are continuously working well!

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for OEM Plastic Arts Factories – Auto lamp cover – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Swansea , Malta , Belgium , To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.