OEM Plastic Needle Factory – Multi-cavity medical mold – DT-TOTALSOLUTIONS Detail:

For more than 10years, we had accumulated very rich experience in designing and building multi-cavity tool for precision small medical parts. They are widely used in medical surgical area, drug delivery area.

This is a 32-cavity mold for parts used in drug delivery system. The plastic for the part is LLDPE35%+HDPE65%. it was exported to Israel.

It has been a great fun to work out this project with our team. The most tricky and fun part of this project is the injection system. Because the part weight is too small with less than 1g, injection flow must be in perfect balance for all the 32-cavity parts. It requires high accuracy to the injection system and hot runner system. Thanks for YUDO’s good cooperation, we had successfully work it through.

For this kind of small precision medical parts, parts from T1 test must be perfect in both dimension and appearance, otherwise new cores or cavities will have to be required. So it is very important all the machining are well controlled with tolerance within +/-0.01mm and +/-0.02mm for some area. High speed CNC milling is required to ensure the tolerance. Precision low-speed wire cutting and mirror-EDM made by GF AgieCharmill are both processed on this tool. This has greatly help us to ensure the accuracy. By strictly control the machining process, bench work on this tool became quite simple.

To make sure customers free of any frustration in long-term production with millions of parts, we had additionally built 14-sets spare parts shipped together with the tool. Considering millions parts are needed to be produced from this tool, and the internal pin is very small, after long-run operating, if there was any issue happened on it, customer can immediately put on the spare pin instead to avoid severe affecting on the mass production.

Another challenge for this tool it’s that it was not easy to find proper injection molding machine that can perfectly suitable for this tool. The parts are too small and too light with 32cavities, the common injection molding machines widely used in China is not so suitable for testing this tool. Based on our experience, if we increase the cavitation to be more, like 64-cavity or more, we can solve the mold better.

We had successful experience in designing and building 100-cavity tool for medical and for caps packing. This is one of our biggest strengths. So please contact DT-TotalSolutions if you are need an expert partner in the field of multi-cavity plastic injection tools!

We had also designed a CCD system together with this tool so it can greatly helpful for customer to inspect the part quality both from dimension and from part appearance. Our plan is to install CCD Checking system for all the tools we made for our customers. This is our extra strength besides just as tool designer and manufacturer.

Come and talk to us, we believe we will both learn a lot from each other!

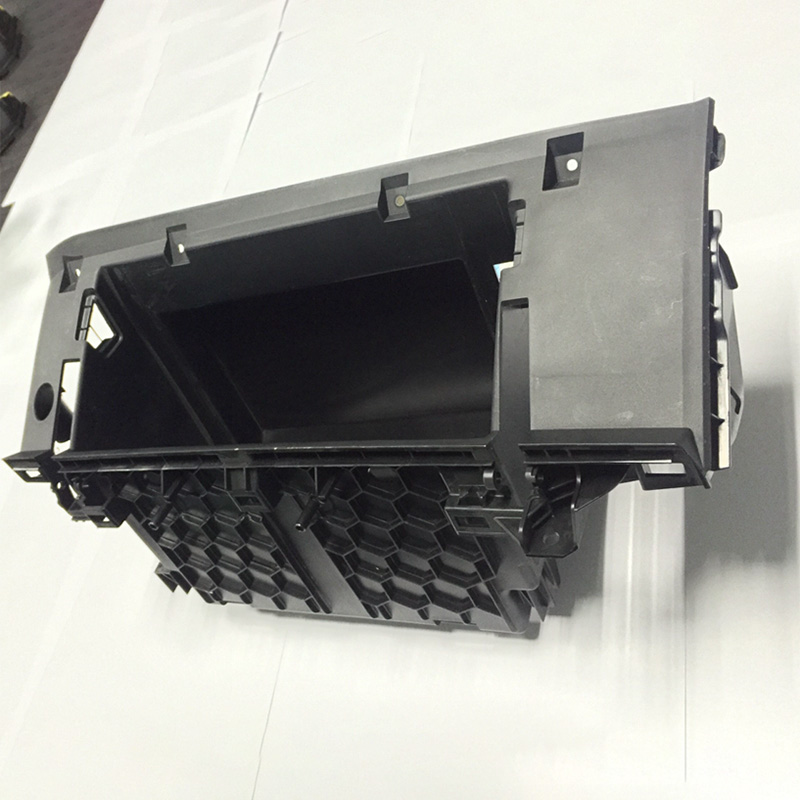

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for OEM Plastic Needle Factory – Multi-cavity medical mold – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Latvia , Ghana , azerbaijan , All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!