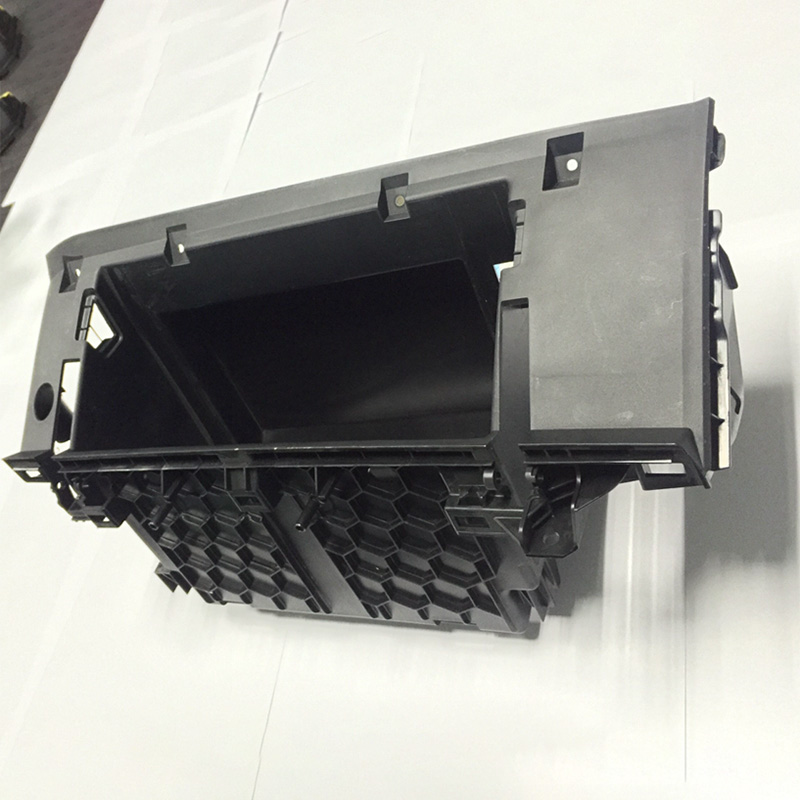

OEM Processing Machinery Manufacturer – Slider internal-thread mold – DT-TOTALSOLUTIONS Detail:

This is a mold with long slider and internal-thread unscrewing system, and the PA6+40%GF. There’s a thread hole at the side of part, and the hole size is relatively small while thread depth are deep.

So The key point is to make sure the unscrewing system running stably and continuously without any issue for long term production of millions of parts.

When designing and building molds for this kind of part, we always do mold-flow analysis first before officially start doing mold design. We analyze the part flow, part thickness, part deformation, part air trapping issue together with injection system exports of hot runner system provider. For parts with high glass fiber, we must choose proper hot runner system cautiously because the long glass fiber may block the hot runner system and plastic leaking can also be a potential issue. We have been working with hot runner system of HUSKY, SYNVENTIVE, YUDO depends on project feature and customers’ budget. We always give the best suitable solution of injection system from the very beginning. Our technical team always communicate with customers’ technical guys directly to make sure smooth communication without any misunderstanding.

To form the thread hole in this mold, we used AHP cylinders to drive the gears to unscrew the internal thread at side of the part. The thread hole in this part is relatively small but the threads are deep. This increased the difficulty to ensure thread accuracy. Because of the inserts for the thread hole is small, to make sure it lasts long enough for producing millions of parts, we have chosen steel of Assab Unimax with hardness reaches to HRC 56-58 with spare inserts made shipped together to customer.

The wall thickness of this part is also a big concern need to pay extra attention. In the thickest area, it reaches to almost 20mm which has potential severe shrinking issue. We had tried many options to find the best injection point position and injection gate size. Our T1 test result shows success on plastic flow with no significant sinking issue. We are proud that we did it with the help of all the analysis we had done and from our previous experience we learned.

We had done this tool with only 2 mold trials before shipping it out to customer’s plant. Now this mold is still running perfectly with thousands of parts produced every year. Every year, we would ask customers’ feedback about all the tools we shipped to them. We do appreciate for all those precious comments we got from our customers which had been a great treasure for us to keep improving.

Now we are going to designing and providing a CCD checking system based on this tool. Because after communicating with customer, they want to save more manpower and increase production efficiency. This is the way how we always providing continuous support to our customers and make new progress together!

If you are interested to know us more, please feel free to contact us at any time. DT-TotalSolutions team is always at your side ready for support!

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for OEM Processing Machinery Manufacturer – Slider internal-thread mold – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Karachi , America , Benin , To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!