OEM Injection Mould For Plastic Manufacturers – Water-assisted mold – DT-TOTALSOLUTIONS Detail:

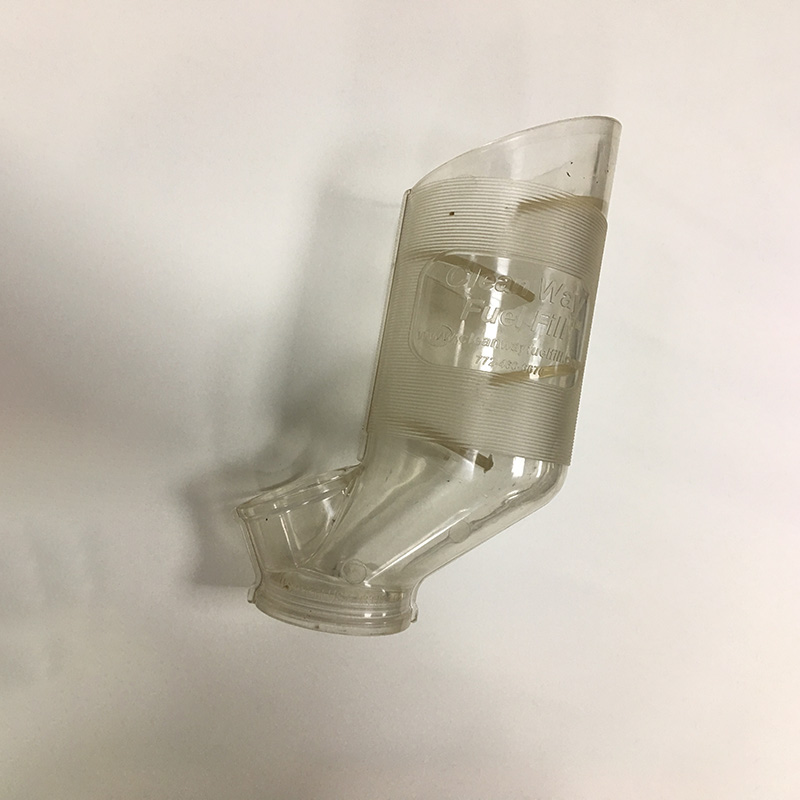

For special shape pipes shown in the picture, it is difficult to get them formed by normal injection mold. Water-assisted technology is a super choice to form these parts efficiently and economically!

Mostly these parts are for water tank of Automotive HVAC system.

To ensure this kind of project success, very tight machining tolerance and super good bench-work are the must factors. Water channel and temperature must be precisely controlled, otherwise the water tank part shape cannot be precisely controlled and the assembly of HVAC will not be succeeded.

We have been designing and building molds for water tank parts of Automotive HVAC system for customers in Europe and USA. Usually before shipping these tools, we will make sufficient test in our house to make sure the tool can run stably and continuously for long-term mass production. At least 4-5 hours simulation run with plastic or dry-run is a must for each tool. All related testing videos and parameters are shared with customers, so they have now concern when they receive the molds.

We have also local technical support in these markets.

In DT-TotalSolutions, we never let go the small detail, and this is how we satisfy our customers for long term.

Contact us, whenever you need a superb tool design and building partner in China.

How important a quality mold is for plastic injection molding mass production?

At the same time, since the mold occupies a large proportion of the production cost of injection molding processing enterprises, mold life directly affects the cost of injection molded products. Therefore, improving the quality of injection molds, maintaining and maintaining them well, and prolonging mold life are important issues for reducing costs and increasing efficiency in injection molding production.

Moreover, the mold structure is also closely related to the cost of injection molding equipment and raw materials.

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for OEM Injection Mould For Plastic Manufacturers – Water-assisted mold – DT-TOTALSOLUTIONS , The product will supply to all over the world, such as: Ecuador , Russia , Greek , We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.