Key point of the machine: the robot take out molded parts

The operation procedure of the machine works as below:

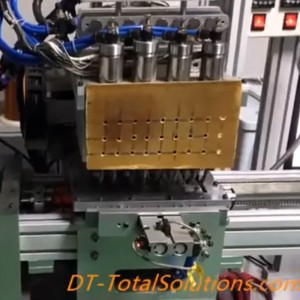

1) The robot has 4-axis, it will input 6 metal-rings into mold cavity, after that will take out insert-molded plastic parts with runner from the core side.

2) Drop the runner

3) Drop the fixture to take the 6 metal rings

4) Check the molded parts quality

5) Sorting up the part by stacking up them

6) Take out the stacked parts to the packing working line

7) Take fixture for taking 6 metal rings

8) Take the 6 metal rings

Move to next molding cycle and repeat above procedure.

By doing so, at least 60% labor can be saved and the total cycle time will be only half of the time by manpower. Also by doing insert by robot, the positioning can be better and precise than putting by hand, there for final molded part quality can be better ensured.

This means the part quality and production efficiency are both greatly improved!